|

Forklift

Version original

Anglais:

howworkliftworks_an Version française

commentfonctionnelecontrepoids_fr

Information: Lien en Web

Anglais

ICI

Operating Information

How a Forklift Works

La documentation française est sur le site en plusieurs

sections. ainsi que les liens attenants.

Check-lists en anglais et en français

Versions :

trucks_stability_an

stabilité des chariots

élevateur.php

Please be sure to read the

Safety information that accompanies this product.

Additional forklift safety information also is available

at the following links:

Types of

Forklifts

Select a

Safe Forklift

Explosion/Combustion

Hazards

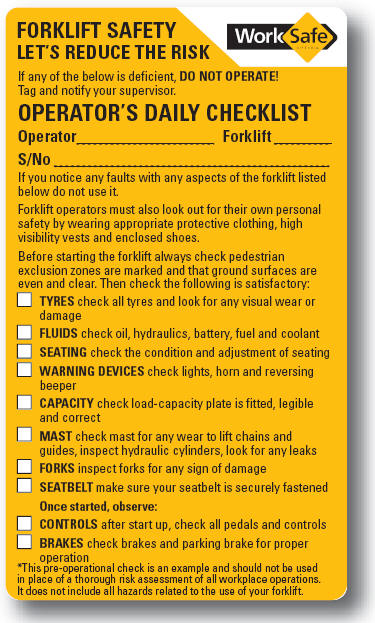

Daily

Checklist (Note: Daily Checklist is in pdf

format) is a sample operator’s “Daily Forklift

Safety Checklist” that can be attached to the forklift

as a reminder to the operator to do this

check.

Voir un

échantillon de

Checklist stickers

La documentation française est sur le site en plusieurs

sections. ainsi que les liens attenants.

Check-lists en anglais et en français.

Driving a forklift is different

than driving a car

In a car or truck the front

wheels steer the vehicle. A forklift has the steering

wheels in the rear. The rear end of the forklift swings

in a circle around the front wheels that support most of

the load. The operator must check that there is room for

the rear end to swing when making turns.

This

clearance can be maintained in your workplace by

permanently marking aisles with painted lines or

arranging storage racks in a way that creates obvious

aisles for travel.

However, these marked aisles

will only be effective if you keep them clear of stored

materials, which can gradually encroach as space is

needed.

A forklift is not as responsive as a car

when turning the steering wheel. Rear steering makes it

difficult to stop a forklift quickly or swerve and still

maintain control. It is important, then not to drive a

forklift fast or round corners quickly.

Driving with the load downhill can result

in loss of the load and control of the

forklift. Driving with the load downhill can result

in loss of the load and control of the

forklift.

|

| Keep the

load uphill to maintain control of the

forklift. |

If

you drive a forklift on an incline, you must keep the

load on the uphill side. Otherwise, you may have no

weight on the wheels that steer and can lose control!

The load could also fall off or cause the forklift to

tip.

Often a large forklift load obstructs the

driver’s view in one direction. It may be necessary to

travel long distances with the load to the rear (in

reverse for most forklifts). Use extra caution when

traveling in reverse.

Forklift safety

features

A backrest extension on the forks

prevents part of the load from falling rearward toward

the operator. This is required when loads are lifted

high and the type of load would allow all or part of it

to fall to the rear under conditions such as

acceleration, sudden stops or driving on an uneven

surface.

An overhead guard prevents an object on

the forks or on a high rack from falling onto the

operator while picking or placing a load at elevation.

The guard is not designed to withstand the impact from a

full load. It can be effective in deflecting small

packages. It is required on all forklifts that can lift

a load above the operator unless conditions such as

clearances would not allow the forklift to be

used.

Operator restraints will hold you in the

seat if you strike an object or if the forklift

overturns. Since 1992, forklift manufacturers have been

required to equip new forklifts with operator restraints

such as seat belts. Many forklift manufacturers offer

restraint systems that can be retrofitted on older

forklifts.

If your forklift begins to overturn,

you are safest when you stay in the seat, hold on

firmly, and lean in the opposite direction of the fall

rather than trying to jump. Many fatal accidents

happened when the operator tried to jump. As the

forklift begins to tip, it will move slowly - tricking

the operator into believing there is time to jump. Once

the center of gravity is past the wheel line, the

forklift will rapidly fall. The forklift’s overhead

guard will quickly pin or crush an operator who

jumps.

Failure to wear a seat belt can result in the

operator being thrown outside the protective cage in the

event of overturn.

Failure to wear a seat belt can result in the

operator being thrown outside the protective cage in the

event of overturn.

If your forklift has a

restraint such as a seat belt or a lap bar, you must use

it.

How forklifts safely carry and lift

heavy loads

A forklift works on the principle

of a cantilever. A load on a beam (the forks) supported

by a fulcrum (the front wheels) is counterbalanced by a

weight on the other end of the beam (the forklift body

and counterweight built into it).

Whether a forklift will

safely carry a load or will tip forward can be

determined by comparing the "moment" of

each. Whether a forklift will

safely carry a load or will tip forward can be

determined by comparing the "moment" of

each.

Moment equals the distance from the fulcrum

to the center of gravity (the point where all the weight

is concentrated) times the weight.

Example: an

evenly distributed 36" wide load on the forks has a

center of gravity that is 18" from the face of the

forks. (Note: The fulcrum point is actually at the

center of the wheel. Forklift load charts, however, are

adjusted to allow measuring from the face of the

forks.) If the load weighs 4000 pounds then the

load moment will be (18" x 4000 lb.) = 72,000

inch-pounds.

If the "moment" of the forklift is

greater than or equal to the 72,000 inch pounds of the

load then the forklift will safely carry the load.

Forklifts have a capacity plate to tell the user what

loads are safe to lift. If the plate says the capacity

is 30,000 pounds or less then that capacity is rated for

a load with a center of gravity 24” from the face of the

forks. If the forklift capacity is greater than 30,000

pounds then the label will rate the load at a 36" or 48"

center of gravity since larger forklifts usually lift

physically larger loads.

For example, a forklift

rated at 5000 pounds would safely lift a load with a

moment of up to (24" X 5000 lb.) = 120,000 inch-pounds.

In this case the load above would be safe to

lift.

|

Forklift Moment = (24" x 5000

lbs.) = 120,000 inch-pounds.

The load is

safe to lift because load moment is less than

forklift

moment. |

However

if the 4000 pound load was 66" wide, the load moment

would be (33" X 4000 lb.) = 132,000 inch-pounds which

would be greater than the moment of the forklift. The

forklift would tip forward.

As the load is raised, it

becomes possible for the forklift to fall to the side as

well as tip forward. The operator must consider the

center of gravity of the forklift and load together.

This combined center of gravity moves as the load is

moved and as the forklift travels over surfaces that are

rough or inclined. As the load is raised, it

becomes possible for the forklift to fall to the side as

well as tip forward. The operator must consider the

center of gravity of the forklift and load together.

This combined center of gravity moves as the load is

moved and as the forklift travels over surfaces that are

rough or inclined.

Forklifts have a "stability

triangle". The sides of the triangle as shown in the

illustration are formed by the center of each front

wheel and the center of the rear wheel or at the center

of the axle if there are two rear wheels.

A

vertical line extending from the center of gravity of

the vehicle-load combination must be inside of the

stability triangle to prevent the forklift from tipping

forward, falling sideways or dropping its load.

The center of gravity of the

forklift-load combination can move outside the stability

triangle if:

- The load is picked up on the tip of the forks,

- The load is tilted forward,

- The load is tilted too far back when raised,

- The load is wide, or

- Forklift movement causes the center of gravity to

shift.

These actions will have the

following effects:

|

Action |

Center of gravity

moves: |

| Tilting the load

forward |

Toward the front

axle |

| Raising the load while

tilted forward |

| Driving on an incline

with the load downhill |

| Stopping forward

travel or accelerating backward |

| Tilting the load

back |

Toward the rear

axle |

| Raising the the load

while tilted back |

| Driving on an incline

with the load uphill |

| Accelerating forward

or stopping backward travel |

| Driving across an

inclined surface |

Toward the downhill

side of the triangle |

| Driving across a rough

or uneven surface |

Toward the rut or low

side of the triangle |

| Turning |

Toward the side now

facing the original direction of

travel |

This list represents operator procedures

that reduce the risk of overturn, collision or loss of

the load. This list represents operator procedures

that reduce the risk of overturn, collision or loss of

the load.

To prevent your forklift from

tipping over, falling sideways or dropping its load:

- Make sure the load is stable and safely arranged

on the forks.

- Do not tilt the forks forward except when picking

up or depositing a load.

- Tilt the load backward only enough to stabilize

the load.

- Keep the load low just above the pavement with

forks tilted back when traveling.

- Cross railroad tracks diagonally when

possible.

- Enter elevators squarely.

- Keep the load uphill when going up or down an

incline.

- Drive at a speed that will allow you to stop

safely within the stability triangle.

- Slow down on wet or slippery surfaces.

- Slow down to make turns.

- Avoid driving over loose objects or on surfaces

with ruts and holes.

|

Checklist stickers |

|

There are checklist stickers

included at the back of this

guide. Be sure to stick them

onto your forklifts. They’re

made of wipe-clean plastic, so

they’re able to be reused again

and again.

|

|

|

| |

|

Source:

Product

| Specs | Operating |

Safety

Version original

Anglais:

howworkliftworks_an Version française

commentfonctionnelecontrepoids_fr

Versions :

trucks_stability_an

stabilité des chariots

élevateur.php |